AISI SAE 4130 4140 4145H Steel Round Bar Hollow Rod

Fitur

Bar baja 4130 4135 4140 4145H minangka baja paduan karbon rendah.Iki kalebu paduan Chrome-Molly sing ngemot kromium lan molybdenum minangka agen penguat.

4130 bar baja bunder nduweni kemampuan kerja sing apik, deformasi pangolahan minimal, lan resistensi lemes banget.Iku belongs kanggo kategori medium kanggo baja kemampuan harden dhuwur.Sawise perawatan panas, 4140 nduweni kekuatan sing apik lan sifat mekanik sing komprehensif, kemampuan proses sing apik, lan ngasilake dhuwur.Suhu layanan yaiku 427 derajat Celsius.

4140 nduweni kekuatan dhuwur, kemampuan harden, kateguhan, lan deformasi sajrone quenching.Nduweni kekuatan creep dhuwur lan kekuatan toleransi ing suhu dhuwur.Digunakake kanggo manufaktur forgings sing mbutuhake kekuatan sing luwih dhuwur lan bagean quenched lan tempered luwih gedhe saka 4135 baja, kayata Gir gedhe kanggo doyo tarik lokomotif, Gir transmisi booster, as mburi, rod nyambungake lan klip spring sing akeh banget dimuat.

Spesifikasi

| Jeneng produk | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Bahan | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Standar | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm nganti 600mm | |

| lumahing | Dicet ireng, Bare, polesan, Chrome Plated | |

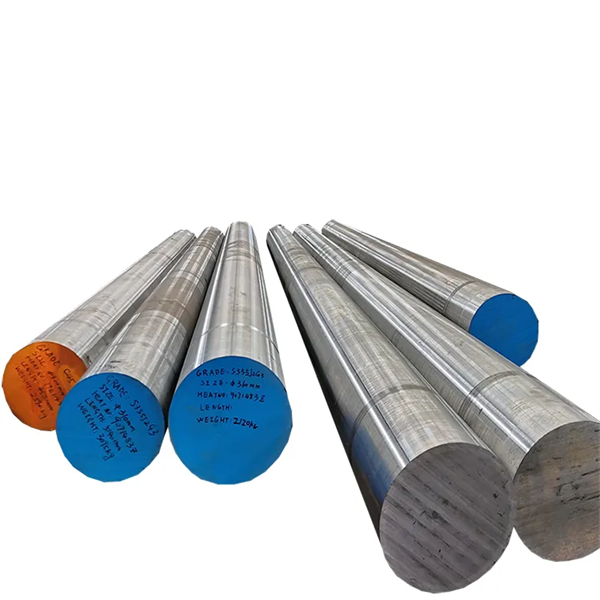

| Spesifikasi | Bar bunder | 8mm ~ 800mm |

| Bar sudut | 3mm * 20mm * 20mm ~ 12mm * 800mm * 800mm | |

| Bar kothak | 4mm * 4mm ~ 100mm * 100mm | |

| Bar sing rata | 2*10mm~100*500mm | |

| Heksagonal | 4mm ~ 800mm | |

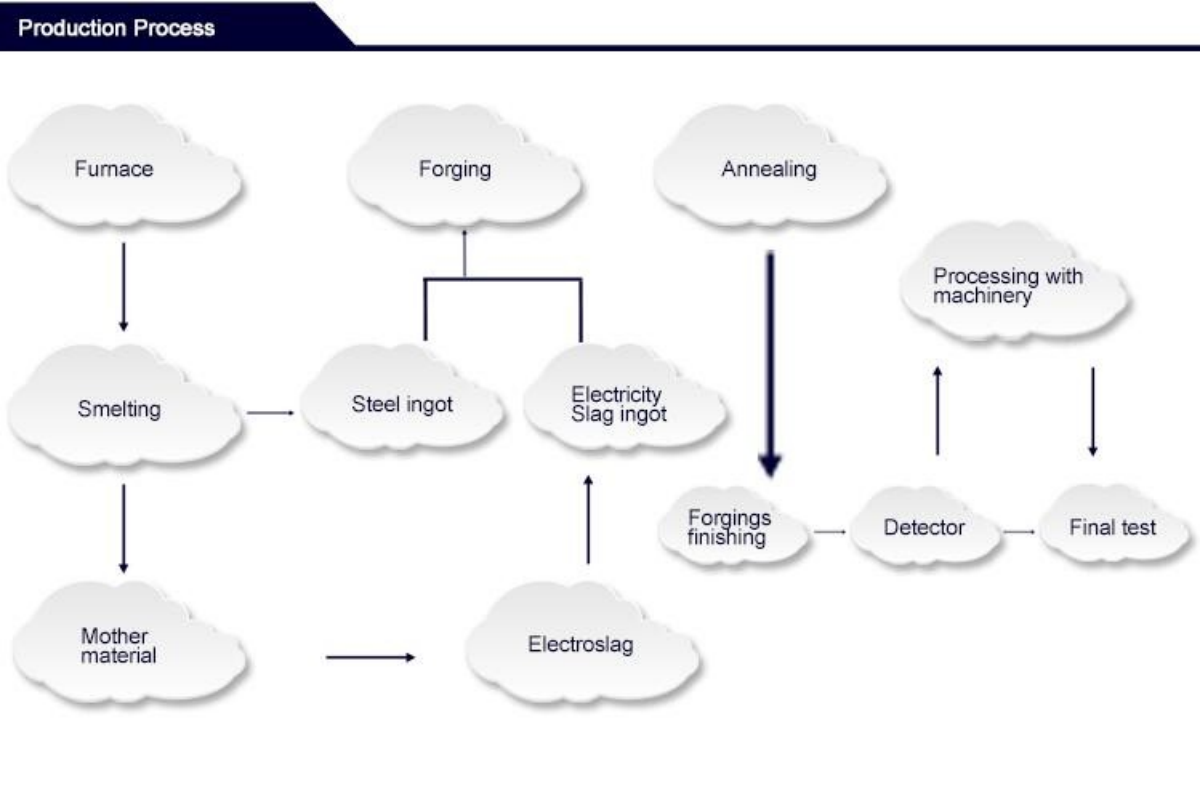

| Proses | Tungku listrik dilebur, ditempa lan anil, bar bunder diuripake. | |

| kekerasan: | HBS 217Max (Beda karo perawatan panas) | |

| Tes UT | SEP 1921/84/2 kelas C/c. | |

| Toleransi | Diameter -0/+ 0~5mm, Ketebalan -0/+ 0~5mm, Jembar: -0/+ 0~10mm. | |

| dawa | 2m, 4m, 5.8m, 6m, 11.8m, 12m utawa kaya sing dibutuhake. | |

| Paket | Packing Layak Laut. | |

| Standar sing beda-beda | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220(34CrMo4) | SCM432 |

| 4145H | — | — | — |

Komposisi kimia

| Komposisi Kimia (%) | |||||||

| sasmita | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0,035 | ≤0,040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0,035 | ≤0,040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0,035 | ≤0,040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0,035 | ≤0,040 | 0.80-1.10 | 0.15-0.25 |

Sifat Mekanik

| ciri: |

| 1. baja paduan Low ngemot molybdenum lan kromium minangka agen penguat; |

| 2.Excellent saka sudut weldability fusi; |

| 3.The alloy bisa hardened dening perawatan panas. |

Toleransi

| Kahanan Pangiriman |

| 1. Digulung panas |

| 2. Anil |

| 3. Normalisasi |

| 4. Quench lan Tempered |

Kondisi perawatan panas

1.Annealing: 880 ℃ Tungku cooling

2. Normalisasi: 880 ~ 870 ℃ Air cooling

3. Hardening: 820 ~ 870 ℃ Water cooling

4. Tempering: 550 ~ 650 ℃ Rapid cooling

Properti mekanik bisa dipikolehi kanthi perawatan panas sing beda.

Paket

1.By bundles, saben mbendel bobot ing 3 ton, kanggo njaba cilik

bar bunder diameteripun, saben mbendel karo 4 - 8 ngudani baja.

Wadhah 2,20 kaki ngemot ukuran, dawane kurang saka 6000mm

3,40 kaki wadhah ngemot dimensi, dawa ing 12000mm

4. Miturut prau akeh, biaya Freight kurang dening kargo akeh, lan gedhe

ukuran abot ora bisa dimuat menyang kontaner bisa shipping dening kargo akeh

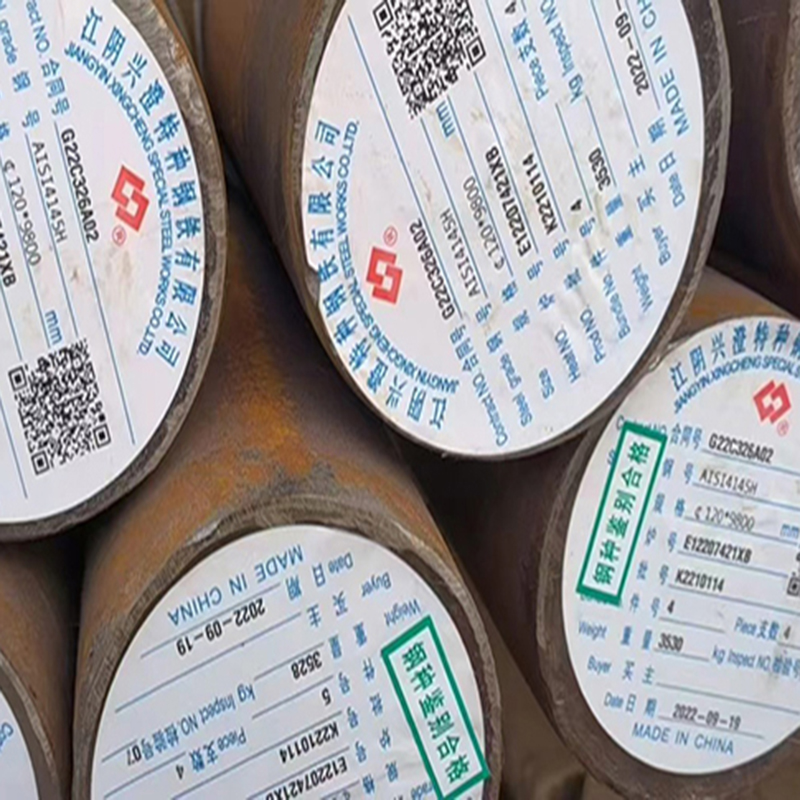

Jaminan kualitas

1. Ketat miturut Requirements

2. Sample: Sample kasedhiya.

3. Tes: Uji semprotan uyah / Tes Tensile / Eddy saiki / Tes komposisi kimia miturut panyuwunan pelanggan

4. Sertifikat: IATF16949, ISO9001, SGS dll.

5. EN 10204 3.1 Sertifikasi